Where great ideas bubble up - Annual Report 2024

8 June, 2025

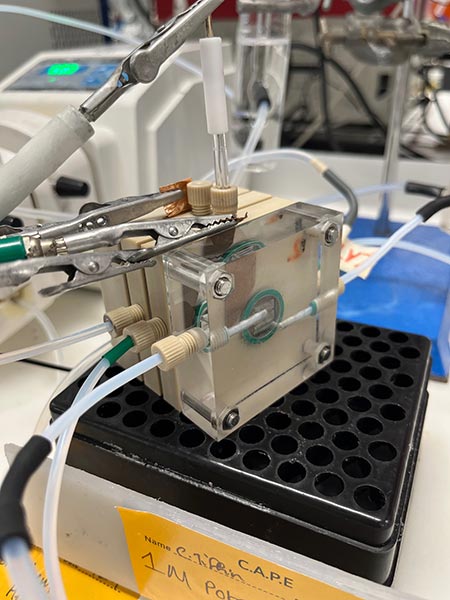

From left: PhD students Shae Patel (McKelvey / Liu lab) and Campbell Tiffin (Marshall lab) conducting electrocatalytic CO2 reduction experiments.

Over the last 150 years, humanity has harnessed chemistry to make products underpinning the modern economy, from fertilisers and fuels to synthetic fibres and pharmaceuticals.

But we still don't fully understand many of the chemical processes underpinning these products, says Te Whare Wānanga o Waitaha University of Canterbury-based MacDiarmid Institute Principal Investigator Professor Aaron Marshall.

"With things like ammonia and methanol production, nobody fundamentally knew how they worked, but the industry figured out how to make them and carried on producing them," says Aaron.

The key to breakthroughs in chemical processes that can help to decarbonise the economy is revisiting chemical processes to gain new insights that radically improve them.

That's the approach Aaron is taking with his work with the Catalytic Architectures research programme at the MacDiarmid Institute, which centres on the electrochemical conversion of carbon dioxide into fuels. It's an area that researchers have been working on for over two decades. During that time, big gains have been made in developing electrode materials with high catalytic performance, the key to driving the adoption of carbon capture, storage and conversion technologies.

The right touch

However, making catalysts efficient enough to offer cost-effective alternatives to simply burning fossil fuels is still a major challenge.

"It's pretty easy to make a catalyst that converts CO2 into something useful like ethylene, or ethanol," Aaron explains.

"Our catalyst is 25% efficient at doing so, which is very good. It's satisfying to switch the thing on and it works. But why did it work? The focus for us over the last few years has been on how reactants interact with the catalytic surface."

Aaron's experiments at the MacDiarmid Institute have progressed from dipping lumps of copper into baking soda solutions and running electricity through it to produce small amounts of methane, to designing gas diffusion cells.

"We discovered that putting copper nanoparticles onto an inert porous support and delivering the CO2 to these nanoparticles through the back of this porous support produces a completely different behaviour," he says.

A breakthrough in the process came courtesy of one of Aaron's PhD students.

"The best way I can describe it is that he simply had the right touch," Aaron says.

It goes from producing 20% ethylene to producing 80% ethylene.

Professor Aaron Marshall MacDiarmid Institute Principal Investigator

Synchrotron insights

Electrochemical gas-diffusion cell purchased using MacDiarmid Catalytic Architecture strategic funding to support collaborative research.

The team is exploring how gas bubbles are pumped through these porous systems and the geometry of the porous structures themselves. Progress to date suggests this area of research may be as or more important than coming up with new catalytic materials.

Aaron says the strength of the MacDiarmid Institute is the ability to explore new avenues of potential as experiments yield promising results.

"A contestable government grant usually involves you pursuing a specific goal for a short period. At the MacDiarmid Institute, we have fairly broad overarching research aims which enable us to dig a bit deeper and occasionally go off on tangents," he says.

The collaboration between the MacDiarmid Institute's Principal Investigators and Associate Investigators is another strength, he says, with researchers like Dr Kim McKelvey, a Te Herenga Waka Victoria University of Wellington-based MacDiarmid Institute Associate Investigator tackling the same set of problems from different angles.

Aaron's next set of experiments will involve using the Australian Synchrotron to look in detail at the composition of gas bubbles. Infrared spectroscopy will be used to examine bubbles under a microscope.

"When we dissolve CO2 in a thin layer of liquid, it generates a gas bubble," explains Aaron.

"We are going to measure the composition of that gas bubble right from the start and see how it changes with time. That's where it all starts, so it seems like a process we should understand."

A contestable government grant usually involves you pursuing a specific goal for a short period. At the MacDiarmid Institute, we have fairly broad overarching research aims which enable us to dig a bit deeper and occasionally go off on tangents.

Professor Aaron Marshall MacDiarmid Institute Principal Investigator

From science to start-ups

A demonstration project for carbon capture and conversion is also on the cards, which Aaron says will showcase the potential of the technology. He's excited to see cleantech spin-off companies emerging from the MacDiarmid Institute and other New Zealand research institutions.

Aaron serves as the Chief Technology Officer of start-up Zincovery, which is making zinc recycling more efficient and sustainable. He's also co-founder of start-up Ternary Kinetics, which is developing zero-emission liquid fuels suitable for existing infrastructure and transport systems, such as power-hungry heavy transport.

His co-founders are Dr Sean Simpson and Sean Molloy, two of the key people behind LanzaTech, New Zealand's most successful cleantech start-up, which listed on the Nasdaq in 2023. Rocket Lab founder Sir Peter Beck is also a director and investor of Ternary Kinetics.

"If you look back over 15 years to the early days of LanzaTech, they were bubbling some gas through a beaker on a bench. It didn't necessarily look like it would go somewhere. Now look at the scale they are operating at," says Aaron.

"Everybody knows that just minimising CO2 isn't enough. We've got to be capturing it, storing it and converting it. I think we've got the right capability to make a difference."

Everybody knows that just minimising CO2 isn’t enough. We’ve got to be capturing it, storing it and converting it.

Professor Aaron Marshall MacDiarmid Institute Principal Investigator