1.3 Painting semiconductors - Annual Report 2017

18 May, 2018

Painting semiconductor surfaces to create sensors

Imagine a point-of-care electronic blood test that can provide an immediate result in a doctor’s surgery, instead of the current tests that have to be sent away to a lab. The blood test device would plug into a mobile phone to provide a reading, and would be cheap and biofriendly. Or imagine a cheap, wearable UV sensor for SunSmart education and skin-cancer prevention programmes in schools. These are just two of the end products that Principal Investigator Associate Professor Martin Allen (University of Canterbury) and his MacDiarmid Institute collaborators are working towards.

The underlying science of these devices is based on changing the properties of metal-oxide semiconductors (such as zinc oxide or tin oxide) by chemically attaching organic molecules; for example, to make them into biological and environmental sensors.

“These are quite unusual semiconductors in that they’re completely transparent, so you can make sensors which are invisible and non-intrusive,” says Associate Professor Allen. “They’re also cheap, nontoxic, biofriendly materials.”

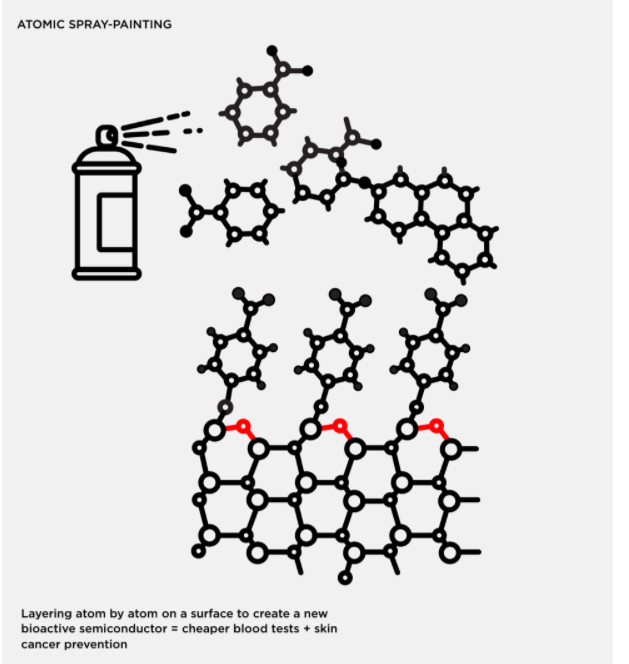

The metal-oxide semiconductors are grown on plastics, glass or sapphire by one of two methods. The first method uses a state-of- the-art molecular beam epitaxy facility to grow semiconductors, using beams of atoms in an ultra-pure vacuum system. “It’s a bit like atomic spray-painting,” says Allen. “We can virtually deposit these layers atom by atom on to sapphire substrates”.

The second method is much cheaper; the equipment involved costs less than $5,000. “This method uses a non- vacuum solution-based system. Ultrasound waves are used to generate a mist of these materials and we can then easily deposit that mist onto whatever surface we want to grow them on,” explains Allen.

A very unusual property of these metal-oxide semiconductors is that they’re covered in free surface electrons. “They have a two-dimensional layer of mobile electrons on the surface, which makes them highly sensitive to their environment,” says Allen. While this is useful for things like atmospheric sensing, it is not so good for other applications. “We get rid of that surface sensitivity using special organic layers, which enables them to sense other things like UV radiation and biological molecules, such as proteins, toxins and antibodies. The organic layers both protect the material and change its properties.”

Associate Professor Allen and his MacDiarmid Institute collaborators have developed a cheap and robust way to get different organic molecules to attach to the surface of these semiconductors, for example by terminating the surface with amino groups. “This means that they’re bio-active and sensor ready,” says Allen.

What Associate Professor Allen likes best about this work is that it is truly multidisciplinary. “Alison Downard is a chemist. Roger Reeves is a physicist. I’m an engineer. And we’re all MacDiarmid Principal Investigators at the University of Canterbury,” says Allen. “And there’s a whole range of multidisciplinary PhD students working together on the project, all learning new things from each other.”

Support for the work has also come from MacDiarmid Deputy Director and Principal Investigator Associate Professor Nicola Gaston (University of Auckland) on the theoretical calculations needed to select the best molecules to use, and Principal Investigator Dr Natalie Plank (Victoria University of Wellington) on nanostructured metal-oxide growth. “Working as a multidisciplinary team has really supercharged the development of this,” says Allen.

A lot of the key equipment that the team needs to grow and understand the materials (including the molecular beam epitaxy facility) wouldn’t have been possible without the MacDiarmid Institute. “There was a big initial investment from the MacDiarmid Institute that allowed us to build a world-leading position in the growth and fabrication of oxide semiconductors,” says Allen. “We also had a breakthrough in terms of how to make devices on these materials, which we patented a couple of years ago.”

The team also does a lot of work at the Australian Synchrotron, a multimillion dollar x-ray facility based in Melbourne. “We use it to work out how the organic molecules attach to the surface and how they change the properties of the materials, particularly in ways in which we want them to,” says Allen.

The team are currently in the proof of concept stage: they have developed a cheap, quick and robust way of painting a surface with organic layers. The next step is to test the sensing ability of the prototype sensors.

“One MacDiarmid Institute PhD student in particular, Alexandra McNeill, a Fullbright Scholar, has done a lot of the development work with the chemical attachment of organic layers,” says Allen. “We also have a couple couple of new MacDiarmid students who will be taking this to the next level, testing the sensing capability of these things.”