Producing technology-critical materials for a low-emission future

5 May, 2022

MacDiarmid Institute scientists try to tip the carbon balance in NZ’s favour.

Across the world, numerous countries have developed lists of ‘critical minerals’ – materials that are of strategic importance to that economy, because of how and where they are used. Rare-earth elements like neodymium, and metals such as titanium, lithium and tantalum are just some examples of these. Each one plays an important role in our daily lives, used in everything from smartphone chips to wind turbines.

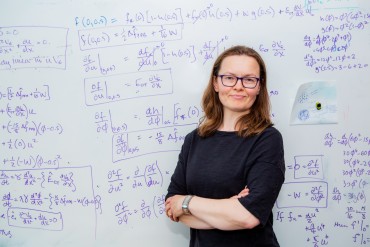

Professor Catherine Bishop

Such materials are not easy to produce. Extracting and refining them comes with significant environmental and financial cost. Despite this, many critical minerals end up in waste streams, while others become low value byproducts. This is a situation that Associate Investigator Professor Catherine Bishop has been working to change for several years. Alongside her colleagues at the University of Canterbury (UoC), Professor Bishop has been exploring the use of a process called molten oxide electrolysis (MOE), which may be able to reduce the carbon footprint of the metallurgical sector. And now, thanks to a successful application for funding from the most recent round of MBIE’s Smart Ideas programme, she will be able to take this work a step further.

“We had originally looked at secondary resources; so we were asking ‘what can we recycle?’ or ‘what can we gain back from this process?’”, she explains. In that research, the focus was on finding smarter ways to utilise the titanium oxides generated by New Zealand’s steelmaking

industry. “We wanted to see if we could do something with this waste material – it is typically crushed up and used as road fill.” The idea was that by heating up this oxide and subjecting it to a specialist, high-temperature type of electrochemistry, they might be able to extract the

titanium metal. “It was stretchy science, we didn’t know if it would work. Ultimately, we concluded that it is possible to obtain titanium from NZ steel slag, but you also get silicon at the same time. It wasn't a straightforward win, but it got us to some of the underlying science.”

From there, Professor Bishop, working closely with her Canterbury colleagues Professor Matt Watson and Professor Aaron Marshall, wondered if a similar technique could be applied to primary processing, particularly of critical minerals. “Could we use electrolysis as a near-zero emission way to extract a rare-earth element from ores of mixed oxides? Or could it be used to pull one metal from chemically similar metals that naturally occur together?” That’s what led the team to identify their two target materials – neodymium and tantalum, both crucial for use in clean energy technologies.

These materials are likely to appear on the forthcoming critical minerals list for New Zealand, as outlined in the government’s Minerals and Petroleum Resource Strategy in 2019. And according to the New Zealand Institute for Minerals to Materials Research, neodymium is just one of the rare-earth elements present in the West Coast’s mineral sands. If Professor Bishop and her multidisciplinary team can find a more efficient, less destructive way to tap into those resources, it could be big business.

She admits that this won’t be without its challenges. “In previous work, we looked at compositions that were fairly common in the steel industry, which meant that some of the fundamental parameters were already known. We had things like phase diagrams, which tell you how stable the

different forms of a material are. For this work, we have to establish and map out those parameters ourselves. The ‘knowns’ are somewhat spotty… though we have identified one materials system that might have legs!”

The experiments, too, will push the boundaries of what’s been done before. Conducted at high temperatures, they will rely on some new facilities at UoC, as she explains, “Aaron and our colleague Matt Watson previously had to go to Australia to do high temperature x-ray diffraction measurements, but we are setting up a similar capability here, which is exciting. Matt also acquired a simultaneous thermal analyser which will allow us to validate other aspects of the phase relations of our materials.”

It was stretchy science.

Professor Catherine Bishop Associate Investigator University of Canterbury

She continues, “This funding mechanism is made for high risk – and maybe high payoff – science. We’re hopeful that within three years, we can demonstrate that there’s something to this idea. Something we can potentially build on in the future.”

This is an attitude shared by Professor Marshall, who was additionally successful in a separate bid for Smart Ideas funding. In that project, he and his team (which includes Principal Investigator Dr Anna Garden) will focus on redox flow batteries. These are long-life energy storage systems

that are effective at capturing the intermittent energy generated from renewable sources, like solar and wind. Currently, these batteries are very expensive, but his aim is to develop new catalysts that speed up the reactions within the battery, improving their efficiency and reducing operating costs.

These projects are both part of the MacDiarmid Institute Catalytic Architectures research programme, which has been designed to support New Zealand’s goal to reach ‘net zero’ carbon emissions by 2050, through clever chemistry and materials science.

Read next

Developing highly functional and tailorable surface coatings